Network System Integration: A Guide to Choosing the Right Optical Fiber Manufacturing Company

One of the crucial factors of a network system integration project is choosing an appropriate fiber cable; they determine the speed and quality of the services that a company provides. So you must be careful when choosing an optical fiber manufacturing company, especially with many available choices. For example, approximately 100 fiber optic manufacturing companies exist in the United States. Therefore, choosing the appropriate cable company for different networking needs can be challenging. One must always remember a few points while picking the proper fiber optic manufacturer.

Identify your requirements

The two basic requirements are speed and distance.

- The distance you need to cover will tell the length of the fiber cable; this may not directly influence the manufacturer’s choice. However, some manufacturers may provide optical fibers at a low cost if you buy fibers above a certain length.

- Network speed is another factor that we must consider while buying optical fibers. This depends on the volume of data transfer. For example, high-speed optical fibers are needed to transfer large amounts of data.

Apart from this, understand the types of optical fibers because there are several ways to fulfil the requirements. There are single-mode, multi-mode, indoor, outdoor, fire-proof, etc. In addition, the fiber counts in the cables will vary; ribbon cables have a higher fiber count than non-ribbon ones. Intermittently bonded ribbon cables offer further higher fiber counts.

Look at the reviews

- List all the companies that can fulfil your requirements; this will make comparing easier.

- The details must contain the company’s location, products, and services.

- Research each company by looking at the review and the positive and negative reviews.

- Start eliminating from the list; eliminate the ones with the worst reviews.

However, keep in mind that reviewers may have a bias against the companies. It could be for or against the manufacturer; this largely depends on their experience. So their points may not be entirely valid, even if the reviewers are truthful. So it is better to consider detailed reviews that mention both pros and cons.

Contact the references

- Phone all the companies on the shortlist and ask for references from them; if the companies don’t give references, keep them on the waiting list. However, don’t eliminate them as their policies may not allow revealing the customers.

- Contact the references and ask for their opinions about the company.

- Things to consider while reviewing the opinions:

- Why did they choose this company?

- What did they like/dislike about this company?

- What can the companies improve?

- These points must enable you to narrow the shortlist further.

While contacting the references, be polite and thank them afterwards. Similar to the case of reviews, be aware of the bias.

Review the company’s experience

As manufacturing fiber optics requires the utmost precision, there is a higher chance of getting a defective product from inexperienced companies.

The defective products are usually the result of poorly designed workflows or wrong approaches. Experienced companies refine their techniques over time. In general, the more experienced companies have a better manufacturing process.

However, it does not mean you eliminate a company just because it’s a startup. Companies that just started may have the latest technologies and proprietary techniques that others have not yet found.

Moreover, starting companies may offer better rates, which leads to the next point.

Check the prices of the Optical Fibres

Price is one of the fundamental aspects that makes or breaks any business deal. And the prices fluctuate. Technological advancements may reduce manufacturing costs and may increase competition. However, new technologies can also be costly because of the patents.

Fiber optics cost a lot more than other equipment because of their complex manufacturing process.

Assess their customer service

Although references and reviews may give a general idea of customer service, asking for technical details about their products will show you the level of their technical service.

Ensure that the company provides a warranty

You should only hire a company if it provides a product warranty; repairing fiber-related issues may be costly, depending on the extent of the damage. A warranty policy must cover all repair costs for at least a year. However, some suppliers provide a warranty that covers several years.

Verify the quality of Optical Fibres

Review and references may help shortlist the companies; however, you must check the quality of each company’s fiber before choosing one. You can get samples of the fibers from the company and check their properties yourself or through a service.

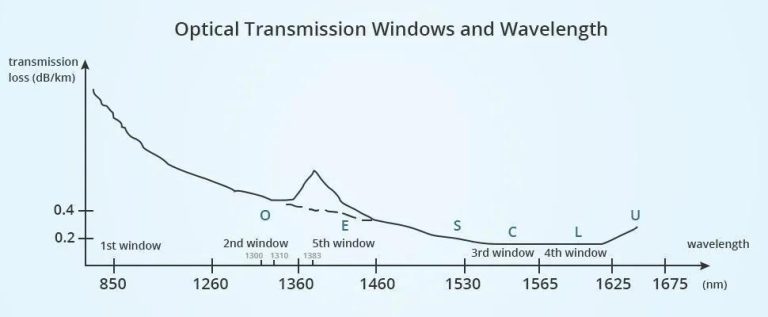

Several fiber optic testing devices in the market can help you measure the loss; ensure that the light loss of the sample is within an acceptable level.

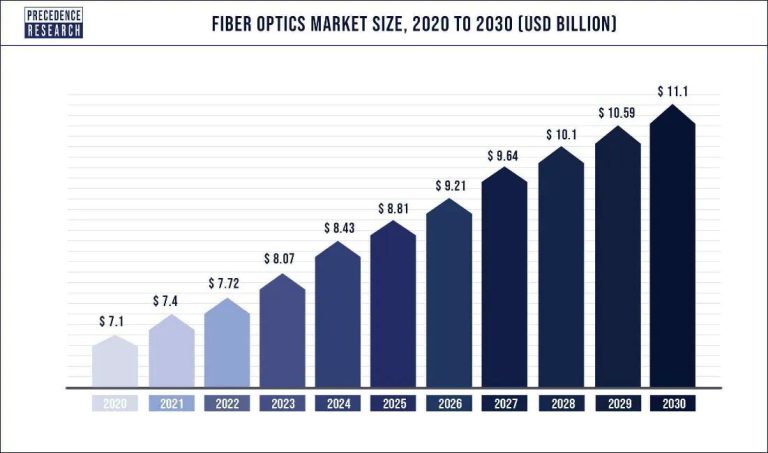

Fiber optic market

Optical fibers transmit data over a considerable distance faster than metal wires. In addition, optical fibers are immune to electromagnetic interference. Therefore, the fiber optic supply market is thriving; it may grow to 8.2 billion USD by 2027. Keeping track of the fiber optics market will also help you choose because it might tell you key market players, the right time to buy, etc.

The fiber optics supply market slowed down during the Covid-19 pandemic; some factories even got shut down. However, others could operate their companies in a limited capacity.

The fiber optic supply market is starting to rise; the two primary factors are the increased preference for remote jobs and the deployment of 5G cellular networks. Both these changes need a robust fiber network, leading to increased demand for fiber optics.

Primary characteristics of the fiber optic market:

- Glass fiber optics will be the most popular type because of their superior qualities and ability to transmit frequencies ranging from 200-2200 nm. So there will be more glass fiber manufacturers.

- Single-mode fibers will take the lead in the fiber optic market because you can send signals faster and over long distances.

- The communication industry will hold a significant share in 2027 optical fiber deployments. This industry enables news & infotainment, point-to-point personal communications, etc.

- The fiber optic market in Asia Pacific will grow the largest; hence, they will have a higher number of manufacturing companies. A higher number of manufacturing companies might reduce the cost.

In conclusion, you need high-quality optical fibers for efficient network systems integration. That means you need to know which manufacturing company suits your needs. You must consider several factors for choosing the appropriate optical fiber manufacturing company, starting with your requirements. For example, how much area do you need to cover, and how much speed do you need? After the requirements are precise, you can search for companies that fulfill those. And you must read reviews about all the companies and contact the references to know about the companies; this will help you reduce your list.

Further elimination will require you to understand the company’s fiber quality, customer support, and price. In addition, ensure you have a warranty for fiber optics covering at least a year. Finally, it would be better to keep track of the fiber supply industry and identify the right time to purchase. This exercise will also provide information about international standards, helping you avoid sub-par services.

FAQs

How do you make optical fiber?

Optical fiber manufacturing is a complex process. It has two steps. First, you create a fiber preform. There are various methods of making a fiber preform. The most common method is chemical vapor deposition. In this method, you blow chemical vapors into a glass tube. These vapors deposit to form the core upon contact with the glass surface. And the glass tube becomes the cladding. The next step is to draw the fibers. Here, you melt the preform and let the melted mass fall under gravity. This mass will pull a thin fiber from the preform.

Does the installation cost higher than the manufacturing cost for optical fibers?

Production cost depends on the process, so it remains largely invariable as a change in manufacturing processes is not rapid. However, the installation process depends on where you have to set up the fiber network. Fiber installation in a hilly area will cost more than in planes. Similarly, the underground installation will require more work, translating to higher expenses. Emerging 3D printing technology is a promising candidate for low-cost fiber optic manufacturing. You can expect this process to lower the production cost than the installation cost.

What is optical fiber testing?

Optical fiber testing refers to checking the transmission quality of an optical network. This process uses several devices to measure the attenuation, insertion losses, and other properties and then compares them with standard values; various organizations, including IEC and IETF, set these standard values. Fibre testing is essential to ensure that you are getting services as per the SLAs. Only then can you expect maximum ROI. Moreover, you should perform the tests routinely to ensure the network does not lose transmission quality due to dust buildup.

What are the parameters of an optical fiber?

Two main parameters to look for while choosing an optical fiber:

- Attenuation: Light signals lose their strength while propagating inside an optical fiber. This process is attenuation; it happens because of scattering and absorption. Light may get scattered because of molecular abnormalities and absorbed due to the presence of impurities, like metals or water molecules.

- Dispersion: Ideal lasers are monochromatic; however, practical lasers are not and contain a narrow range of frequencies. These travel at different speeds in a medium, causing dispersion.