FTTH drop cable production line

- Satisfaction guarantee

- Fast delivery

- Quality assurance

Description

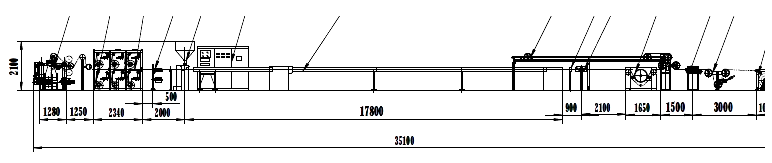

This production line is used for making FTTH cable. The line main components are:

Fiber pay-off, Strength member(FRP or Steel wire) payoff, Self suspending strength menber pay-off, Swing arm type dancer, Extrusion group 65mm, Cooling system, Cable dryer, Dual-axis diameter gauge, Ф600 wrap belt capstan, 70m Horizontal accumulator, Take-up and traversing unit, Electric control system .

| Technical parameters | |

| Producing speed (when 3*2mm FTTH drop cable) | 100m’min |

| Fiber pay-off | up to 8 |

| Extruder | 65mm |

| Cable accumulation length | 70m |

| Installation power | 50-60kw |

| Electrical control system | Siemens PLC + Touch screen |

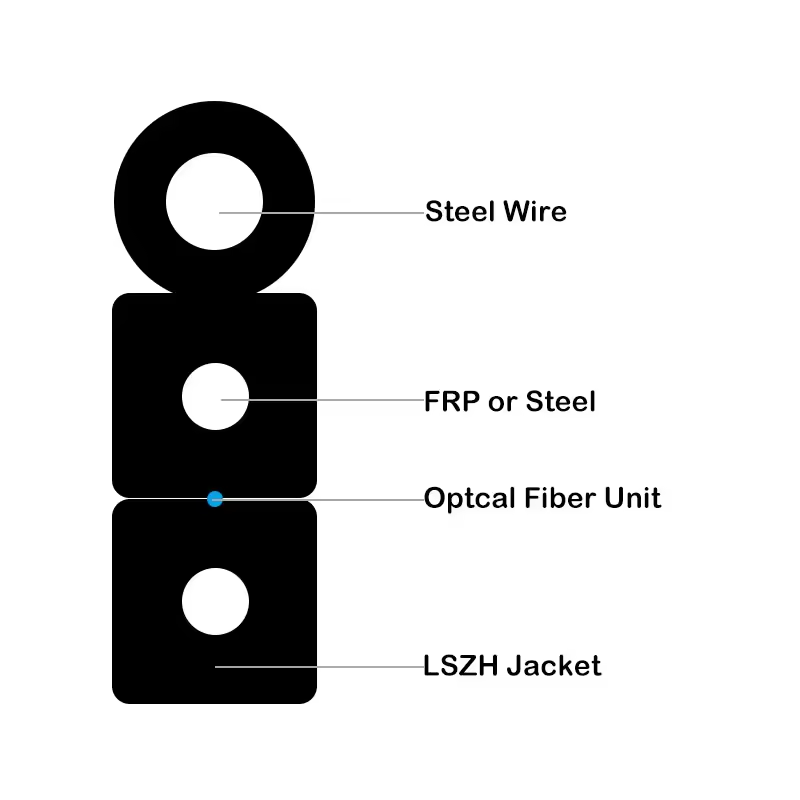

1.Application for FTTH Outdoor Indoor Drop Cable Manufacturing Machine:

FTTH Outdoor Indoor Drop Cable Manufacturing Machine is mainly used to produce 1-12 cores flat and round FTTH drop cable, The material can be LSZH, PVC .This cable Used as access building cable in premises distribution system.

2.Technical parameters of FTTH Outdoor Indoor Drop Cable Manufacturing Machine :

| No | Item | Paramters |

| 1 | Structure Speed | 190m/min |

| 2 | Max.Production Speed | ≥ 120m/min for LSZH material |

| 3 | Optical fiber bobbin size | Φ236 x Φ160 x Φ108 or Φ300 x Φ160 xΦ250 |

| 4 | Optical fiber tension | 0.5~3N (adjustable) |

| 5 | Take-up tension | 5~20N (adjustable) |

| 6 | Take-up bobbin size | PN400-PN 630mm |

| 7 | Length of line | 26m |

| 8 | Central height of line | 1000mm |

| 9 | Power | 50KW |