Indoor fiber optic cable tight buffer production l

- Satisfaction guarantee

- Fast delivery

- Quality assurance

Description

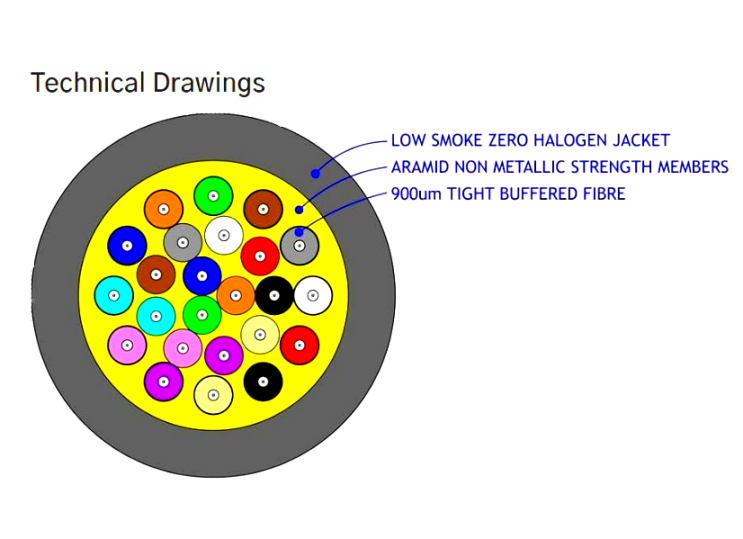

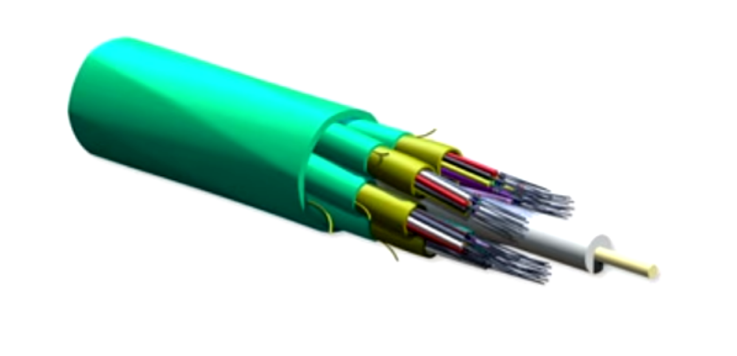

Indoor fiber optic cable is a cable made up of optical fibers that have been processed into a cable with a protective plastic jacket and sheath. The cable consists of a certain number of optical fibers that bundle together in a specific way to form the cable core, which then covers with tight buffer.

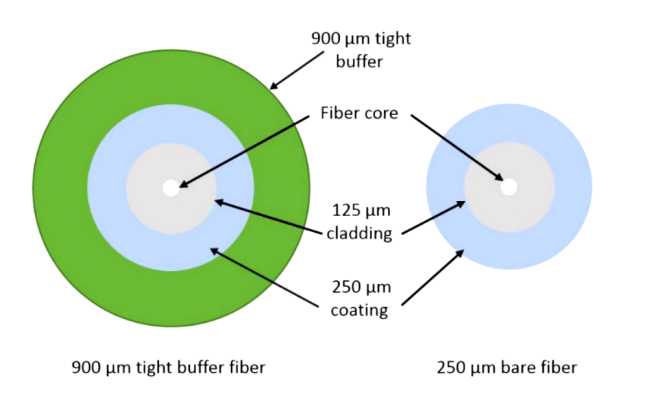

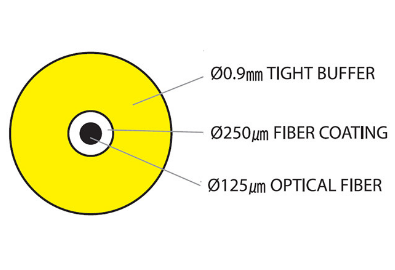

Tight-buffered fiber cable consists of several tight-buffered fibers consolidated in a single cable. Compared with the bare fiber, the tight-buffered fiber is coded with an additional 900um layer over the 250um fibers for protection (as shown in the following picture). Generally, the tight-buffered distribution cable comes in various fiber counts ranging from 2 to 144 fibers. Indoor fiber optic cable tight buffer producation line machine is used to manufacture tight buffer.

| Material: | PVC/LSZH/Hytrel | Design Speed: | Max.300m/min |

| No Of Fiber: | 1 | Excess Loss After Extrusion: | 1550nm<=0.2dB/km(single Mold Optical Fiber) |

| Usage: | Manufacturing Of Tight Buffered Fiber | Warranty: | 18month |

| Voltage: | 3-phase 5wire 380V 50HZ | PLC: | SIEMENS |

| High Light: | 30KW fiber optic cable production line, tight buffered fiber optic cable production line | ||

1. Description for 30mm Tight buffered Fiber Optic Cable Production Line:

This Optical fiber cable production line makes fiber optic cable buffer 0.6/0.8/0.9mm. Cable structure: bare fiber + LSZH/PVC /hytrel sheath, and other similar cables.

2. Features for 30mm Tight buffered Fiber Optic Cable Production Line:

A.High configuration,the machine use IPC+PLC control system.

B.Main electric parts are importing,screw adopt the modern latest technology.

C.Gear tooth surface abrasion resistance.Low energy consumption of the equipment,a large quantity of extrusion, high production efficiency, high gloss surface,small temperature difference,low noise, good stability, strong continuity of working, convenient operation, long service life.